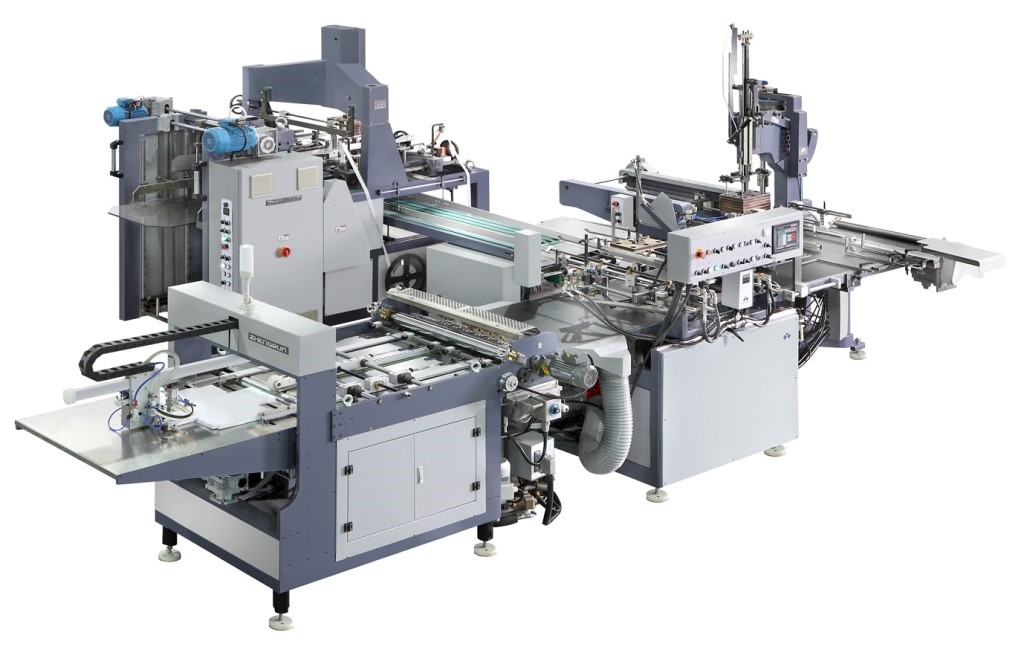

RB420 Automatic Rigid Box wopanga

| Chitsanzo | Mtengo wa RB420 | |

| 1 | Kukula kwa pepala(A×B) | Min.100×200mm |

| Max.580×800mm | ||

| 2 | Kukula kwa bokosi (W×L) | Min. 50 × 100 mm |

| Max.320×420mm | ||

| 3 | Makulidwe a pepala | 100-200g / m2 |

| 4 | Unene wa makatoni (T) | 1-3 mm |

| 5 | Kutalika kwa bokosi (H) | 12-120 mm |

| 6 | Kukula kwa pepala lopindika (R) | 10-35 mm |

| 7 | Kulondola | ± 0.50mm |

| 8 | Liwiro | ≦28mapepala/mphindi |

| 9 | Mphamvu zamagalimoto | 11.8kw / 380v 3 gawo |

| 10 | Mphamvu ya heater | 6 kw |

| 11 | Kulemera kwa makina | 4500kg |

| 12 | Kukula kwa makina (L×W×H) | L6600×W4100×H 2500mm |

1. Makulidwe a max ndi ang'onoang'ono a mabokosi amatsatiridwa ndi mapepala ndi mtundu wa pepala.

2. Kuthamanga kwa makina kumadalira kukula kwa mabokosi.

3. Sitimapereka mpweya wa compressor.

Mgwirizano wofananira pakati pa ma parameter:

W+2H-4T≤C(Max) L+2H-4T≤D(Max)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

1. Wodyetsa mu makinawa amatenga njira yodyetsera kumbuyo, yomwe imayendetsedwa ndi pneumatically, ndipo mawonekedwe ake ndi ophweka komanso omveka.

2. M'lifupi pakati pa stacker ndi tebulo chakudya kusinthidwa concentrically pakati. Opaleshoni ndi yosavuta popanda kulolerana.

3. Zatsopano zopangidwa ndi mkuwa scraper zimagwirizana ndi chogudubuza kwambiri, popewa kupukuta mapepala. Ndipo chofufutira chamkuwa chimakhala cholimba.

4. Adopt kunja akupanga awiri pepala tester, zokhala ndi ntchito yosavuta, amene angathe kusunga zidutswa ziwiri mapepala kulowa makina nthawi yomweyo.

5. Kuthamanga kwachangu, kusakaniza ndi gluing dongosolo la guluu wotentha-kusungunuka. (Chida chosankha: mita ya viscosity ya guluu)

6. Tepi yosungunuka ya pepala yotentha yotumiza, kudula, ndi kumaliza kumata bokosi lamkati la quad stayer (makona anayi) a makatoni munjira imodzi.

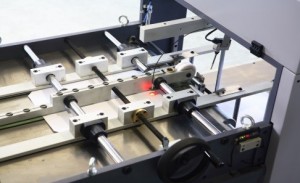

7. Chokupiza choyamwa vacuum pansi pa lamba wotumizira chimatha kuteteza pepala kuti lisapatuke.

8. Mapepala ndi makatoni amkati amagwiritsira ntchito chipangizo chowongolera cha hydraulic kuti chiwoneke bwino.

9. Chokulungacho chimatha kukulunga nthawi zonse, pindani makutu ndi mapepala kumbali ndi kupanga njira imodzi.

10. Makina onse amagwiritsa ntchito PLC, photoelectric tracking system ndi HMI kuti apange mabokosi okha mu ndondomeko imodzi.

11. Imatha kuzindikira mavuto ndi alamu moyenerera.